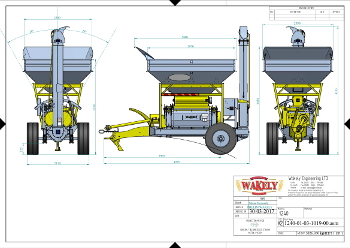

1240 Grain Mill & Crimper Mill

The 1240 Compact is designed for large farmers or contractors. It is ideal if you need to roll or flake large volumes of dry grain quickly.

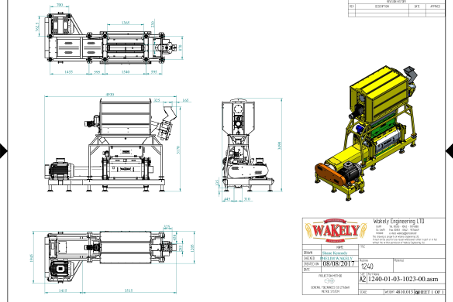

1240 Electric Grain Mill

The Wakely 1240 Electric roller mill is the high capacity mill for industrial milling. This grain mill is ideal for feed compounders who need a reliable, efficient, low maintenance mill.

Extremely versatile. Configure it YOUR way

The Wakely 1240 gives you many options. We can configure your new machine in several different ways, depending on its intended role. Talk to us about what you want and we can provide a machine to suit you specifically.

Wakely Mills Are Built To Solve Problems

Every element is carefully designed to do its job in the most efficient and effective way. Small changes make a big difference. Wakely mills are loaded with useful features, each with its very specific purpose.

50% less electricity used. Roller grinders use at least 50% less electricity when compared to hammer mills, The one-pass system grinds the grain, rather than circulating the grain until correctly sized.

No screen changing. No screens are required to achieve a different grist, simply alter the roll gap handle for instant results, from a coarsely broken sample to a fine grist.

Minimal heat produced. Processed grain is cool to the touch, the roller grinders one pass system, eliminates grain heating which occurs in hammer mills.

Much Less Dust. Particle size less than 300μm are considered hazardous to people and livestock animals. The operator controls and one pass grinding greatly reduce the dust produced.

Wakely. Quality you can rely on.

Some features of the Wakely 1240

Output of 13.0 tonnes barley (per hour) at 12% moisture, producing a finely ground sample 0.8 μm or less

Output of 22 tonnes barley (per hour) at 12% moisture, producing a coarsely ground sample 1.2 μm

Fluted solid chilled rolls 1200 x 400mm

Rolls have double row spherical bearings

Bearings in heavy duty plummer blocks

One-touch operator controls

Weight 4,500 kg

Size: L 4930 x W 1945 x H 1500 mm

One-touch operator controls

Weight 4,500 kg

Size: L 4930 x W 1945 x H 1500 mm

Wakely. Quality you can rely on.

Industrial Grinders From 8 – 20 TPH

Grind, crimp or roll to your exact specifications, all the time, every time. Year after year of trouble-free operation with a full range of complementary equipment such as grain cleaners, electrical controlling systems and more. Industrial grinders in two sizes, ranging from 8TPH to 20TPH. No matter what you need, we have a machine to suit you.

Range of Add-ons and Attachments

Our machines can stand alone or can integrate into a system that includes rubble separators, magnet tables, pin feeders, augers, conveyors, treatments systems and more. We have been working with contractors and industry for more than 40 years. We can find (or create) a solution for you.uit you.

Some of Our Clients:

As part of the new Glanbia development in Portlaoise, two Wakely Industrial Mills were installed for our GAIN coarse ration production. Glanbia’s assurance of consistent top quality product to our customers and a safe, healthy working environment for our staff were met with these user friendly and efficient mills. I found the people at Wakely Engineering to be highly professional and focused in their approach to our needs and delivered in a competent and responsive manner.

“Speedy and friendly service has always been my experience of Wakely Engineering”

Hyde Feeds is Grain Merchant & Miller, who specializes in horse and calf rations. My old roller mill was getting tired. I wanted a larger capacity machine then my 20 Wakely mill, but with the same flat rolled sample with minimal dust. Depending on growing conditions the grain size can vary significantly, I wanted to quickly alter the sample.

The requirements were clear, a premium sample, pleasant working environment, machine capacity of 5-7 tonnes, an installation frame, discharge auger and a completed electrical panel. A specific flute type was chosen to match the specific needs, the installation frame was fabricated with forklift skids for ease of movement. A 200mm discharge auger rotating at low revolutions to preserve the sample was used. ͞The machine’s installation went smoothly and the forklift skids really helped when the mill was being mounted. The machine’s output rating was accurate. I can easily adjust the sample when rolling Barley, Beans, & Oats with the same premium sample. Dust & noise have dropped significantly since the machine’s installation.

“I bought my first Wakely Industrial Mill the Mid 80′s and have worked with them since. Reliability and high output are two critical issues for me –The Wakely Mills deliver both.