Contractor Mill 1240

The 1240 contractor mill is designed for today’s grain contractor, its rugged undercarriage allows for fast travel over long distances and smoothly over rough terrain.

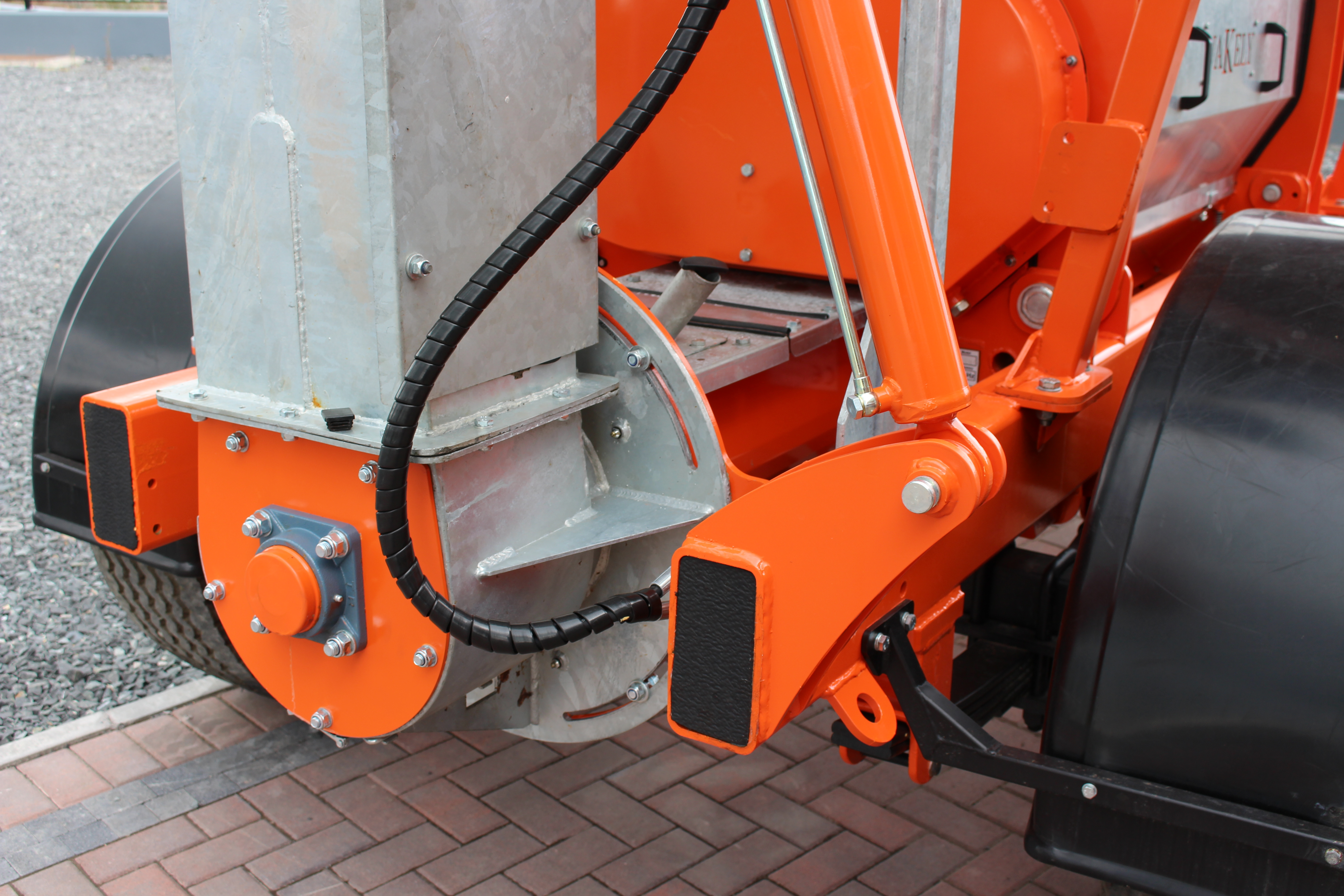

Our integrated applicators can store 2000Litres of alkaline or acidic preservatives. These applicators allow the contractor to travel from farm to farm, dry rolling, flat rolling, crimping and grinding grain for farmers. The easy flow adjustment of these applicators makes it ideal for applying a range of minerals and proteins. All combinable grains beans peas maize oats barley etc are easily processed with our fluted solid chilled rolls guarantee long service. Maintenance is easily completed with our easy access points. Bearings are easily greased from a central location.

After rolling large volumes of grain particularly with alkaline products the mill will require a thorough cleaning, power washing & drain ports allows this to be finished in minutes, eliminating future downtime. We have offer volume and weight based throughput recording. Contractor can provide customer with a receipt for work done. Multiple discharge options are available for the mill including a conveyor, elevator, auger or bagged into a sleeve.

Horsepower requirements for this machine are 180Hp.

Output up to 32 – 37 Tonnes Dry rolling Barley 16% Moisture, producing a broken grain sample.

Output up to 40 – 45 Tonnes Crimping Maize 28% Moisture, producing a lightly bruised sample.

Output up to 34 – 39 Tonnes Dry rolling adding Minerals & Molasses, Producing a Concentrate ration.

Output up to 15 – 20 Tonnes Flat rolling Barley 19% Moisture, producing a flat rolled sample.

Output up to 24 – 27 Tonnes Crimping Maize 28% Moisture, producing a lightly bruised sample.

Output up to 16 – 22 Tonnes Dry rolling adding Minerals & Molasses, Producing a Concentrate ration.

No Roll to Roll contact.

1240*400mm High quality precision balanced Solid Chilled Rollers. 50-53HRC.

180Hp requirement.

PLC Volume capacity System. Option of weight based system.

Rear hoppers have capacity of 4-6 Tonnes per hour.

Trough auger Diameter 250mm, 4.2M Length.

Available as mobile PTO or PTO static versions.

Different roll differentials available depending on the animal being fed.

Various grain discharge options available.

Hopper 5.3 Tonne Maize capacity, with viewing ports.

Wheel 8 Stud 22.5″ 65 / 385 10 Stud option also.

Axles 90*90 8 Stud, 2 Centre arms. Drum size 300*90, 9000kg capacity each.

Cast helical gears powering Rolls, immersed in Oil.

Spring OR Hydraulic roll tension.

Magnet tray on all Machines.

Supplied with T-10 PTO Shaft, with Shear bolt & Overrun.

Sound suppression System for reduced vibration.

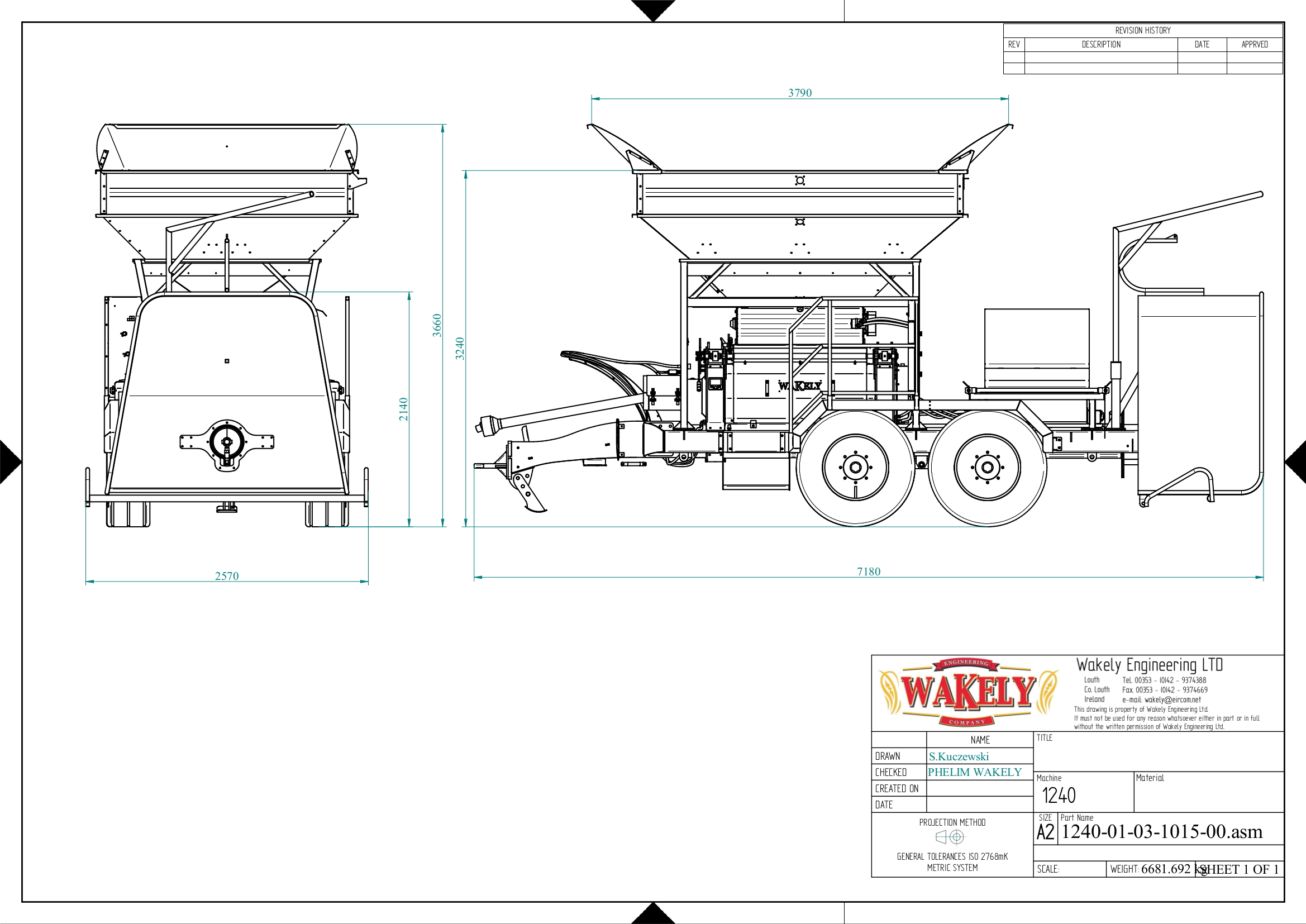

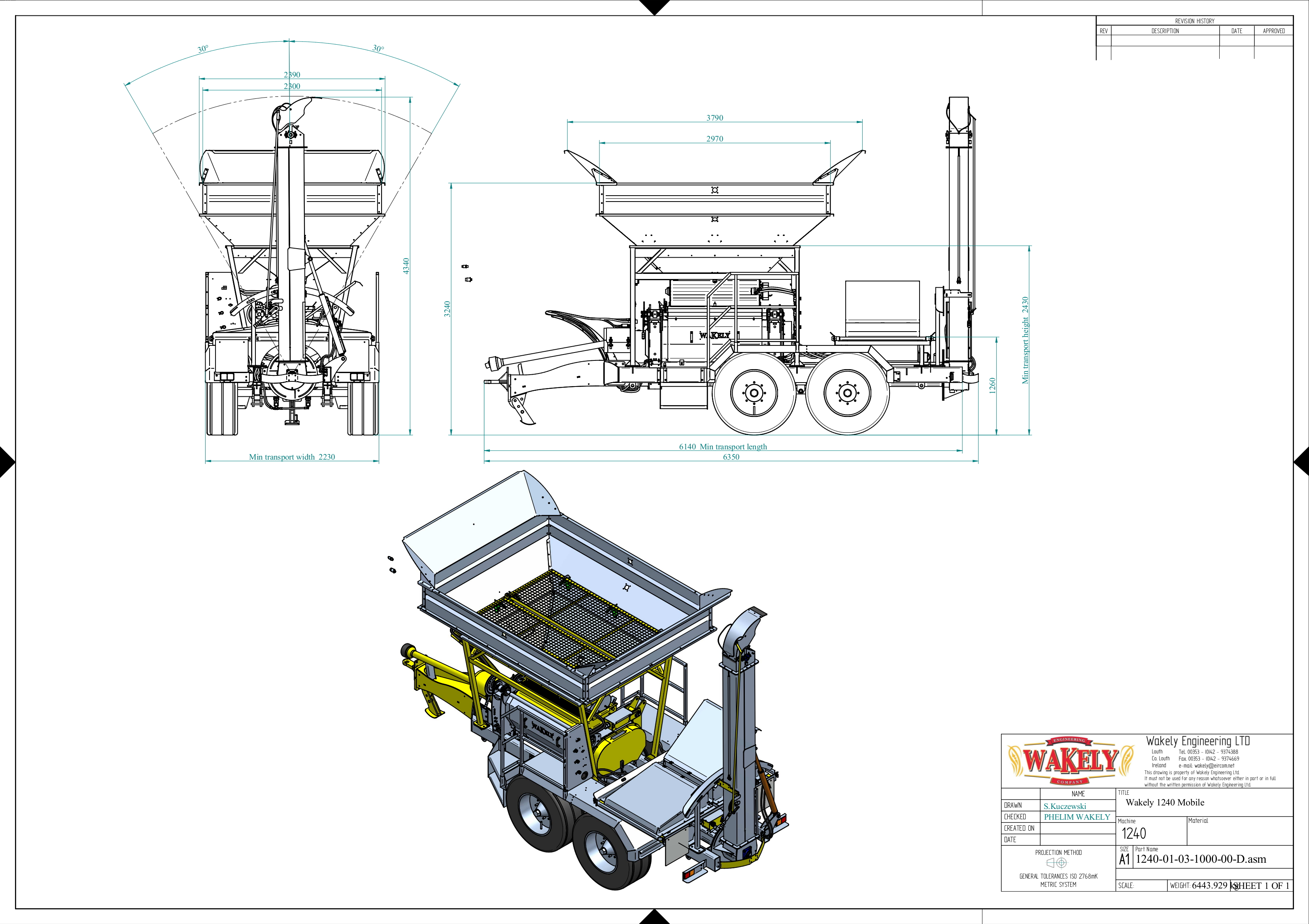

Weight 6900Kg. Length 6350 * Width 2230 * Height 4040 mm.