Benefits of Solid Chilled Rolls.

by Sheila on March 20, 2012

A major decision when a farmer is considering to purchase a Roller mill is whether to opt for Solid Chilled Rolls (S.C.R) or hollow Rolls.

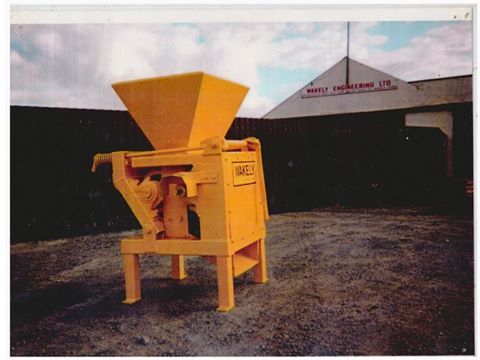

Wakely Engineering LTD was established in 1979 and have consistently used S.C.R in all there mills, This is due to a number of factors.

Roll characteristics.

S.C.R are manufactured from a high grade cast iron,utilizing the double pour Centrifugal cast technique.

Hollow rolls are generally manufactured from Mild steel.

S.C.R Results in.

Long operating lifetime & Roll surface will not be marked/chipped by stones or mild steel bolts. More maintenance for hollow rolls,Roll replacement, Re fluting, When under pressure hollow rolls tend to flex in the centre and results in an unsatisfactory crush, A consistent product is not possible using hollow rolls.

Roll Hardness.

Some manufacturers fabricate their rolls from 12-30mm Mild steel tubing, Wakely S.C.R have a hardness of 50/54 Rockwell to a depth of 30mm & cannot be marked by a file.

S.C.R Results in.

S.C.R have a extremely long roll lifetime, This is due to the Roll characteristics, Roll hardness and the depth of hardness, The rolls can be Skimmed and Re fluted numerous times. Hollow rolls will not hold there fluting edge and needs constant maintenance.

Maintenance.

As a result of the previously mentioned advantages, The maintenance of S.C.R is kept to a minimum, Re fluting is typically carried out after 25000 tonnes depending on the application. Mild steel & Case hardened rolls require servicing & re fluting throughout the season.

S.C.R Results in.

Less Maintenance & down time with a consistent product.

Operator Comfort.

An important factor to consider, The operator can be effected in two main ways (A) Noise levels (B) Vibration levels.

Non S.C.R have by far the highest dB levels & most noticeable Vibration levels, This is caused by the hollow nature of the rolls (Drum effect). In many cases when using hollow rolls & case hardened rolls,it is necessary to force the rolls together to achieve a satisfactory output & finish

S.C.R do not touch & are completely solid, Vibrations are almost eliminated.

S.C.R Results in.

Increased operator Comfort & Efficiency.

Cost.

The initial purchase cost of S.C.R is higher when compared to hollow rolls, However this investment is easily recouped over the operating lifetime.

S.C.R Results in.

75% less Maintenance/Down time, More energy efficient & Less diesel used (where applicable)

Versatility.

Stones & bolts which come into contact with the rolls,will not cause any damage or effect the output of the machine. These rolls are utilized in many different industries from food preparation to mining and other heavy industries.Benefits of Solid Chilled Rolls.

by Sheila on March 20, 2012

A major decision when a farmer is considering to purchase a Roller mill is whether to opt for Solid Chilled Rolls (S.C.R) or hollow Rolls.

Wakely Engineering LTD was established in 1979 and have consistently used S.C.R in all there mills, This is due to a number of factors.

Roll characteristics.

S.C.R are manufactured from a high grade cast iron,utilizing the double pour Centrifugal cast technique.

Hollow rolls are generally manufactured from Mild steel.

S.C.R Results in.

Long operating lifetime & Roll surface will not be marked/chipped by stones or mild steel bolts. More maintenance for hollow rolls,Roll replacement, Re fluting, When under pressure hollow rolls tend to flex in the centre and results in an unsatisfactory crush, A consistent product is not possible using hollow rolls.

Roll Hardness.

Some manufacturers fabricate their rolls from 12-30mm Mild steel tubing, Wakely S.C.R have a hardness of 50/54 Rockwell to a depth of 30mm & cannot be marked by a file.

S.C.R Results in.

S.C.R have a extremely long roll lifetime, This is due to the Roll characteristics, Roll hardness and the depth of hardness, The rolls can be Skimmed and Re fluted numerous times. Hollow rolls will not hold there fluting edge and needs constant maintenance.

Maintenance.

As a result of the previously mentioned advantages, The maintenance of S.C.R is kept to a minimum, Re fluting is typically carried out after 25000 tonnes depending on the application. Mild steel & Case hardened rolls require servicing & re fluting throughout the season.

S.C.R Results in.

Less Maintenance & down time with a consistent product.

Operator Comfort.

An important factor to consider, The operator can be effected in two main ways (A) Noise levels (B) Vibration levels.

Non S.C.R have by far the highest dB levels & most noticeable Vibration levels, This is caused by the hollow nature of the rolls (Drum effect). In many cases when using hollow rolls & case hardened rolls,it is necessary to force the rolls together to achieve a satisfactory output & finish

S.C.R do not touch & are completely solid, Vibrations are almost eliminated.

S.C.R Results in.

Increased operator Comfort & Efficiency.

Cost.

The initial purchase cost of S.C.R is higher when compared to hollow rolls, However this investment is easily recouped over the operating lifetime.

S.C.R Results in.

75% less Maintenance/Down time, More energy efficient & Less diesel used (where applicable)

Versatility.

Stones & bolts which come into contact with the rolls,will not cause any damage or effect the output of the machine. These rolls are utilized in many different industries from food preparation to mining and other heavy industries.