People have being busy making beer for approximately 5,000 years, presumably they enjoyed the refreshing taste and the relaxing effects it has on the body after a hard days work…. the process is still the same today!

A point which likely didn’t concern the Neolithic people was Two or 6 Roll Barley.

[nggallery id=97]

Two row Barley is preferred in the production of Beer as it has lower Protein levels, higher starch levels & a thinner husk. Six row Barley is usually used for Feed production, it has High protein levels, A heavy outer husk and is said to have a ‘Grainer taste’.

Though in other regions, 6 Row barley is used, and is liked and enjoyed

For those interested in Malting Barley varieties find some information here and here.

The common process in making Beer is as follow’s,

– Steeping > Grain is loaded into a vessel, water is added and over the next 40 – 48 hours the grain is submerged and drained until the grain has reached a moisture content of between 40 & 44% moisture content, The steeping encourages the Barley to ‘Chit’ ie germinate.

– Germination > The germination is continued in this stage which will last approximately 4-5 days, the reason for this is to allow the protein and carbohydrates to be broken down and to gain access to the starch stored in the grain, which will be critical in the following stages.

–Drying > The sprouting of the Grain is stopped by reducing the moisture content of the grain to a set moisture content, Varying the temperature & the duration of the drying will add flavour characteristics to the beer.

[nggallery id=98]

– Milling > The Grain has now being appropriately conditioned, it is now at a moisture content of approximately 9%, A suitable malt mill is required to produce a grist, care should be taken to not Under or Over crush the Grain, Under crushing will result in poor mash efficiency, Over crushing will result in a blocked sparge, ie the fine dust will block your system. The correct grist is were little flour is produced, but the Husk is separated from the Endosperm.

– Mashing > Malted barley, Hops & hot Water are added and agitated in the mashing tank, the purpose of this is to convert the grain starches into fermentable sugars.

– Fermenting > Nearly there!, Here the sugars are fermented into Alcohol, this occurs in a separate tank that is sealed from the outside environment, the length of Fermentation will vary depending on the Beer your producing and the number of tanks in your system, 2 to 4 Weeks is a general guide.

– Conditioning > This stage puts the fizz in your beer, The Wort as it is called is then transferred to a sealed pressurised tank in a cool environment, where the temperatures are constant, there are a number of different methods. The most common is to pump CO2 into the tank until it dissolves. This process takes between 2 to 3 weeks.

– Filtering > This stage is sometimes bypassed by home Brewers as the beer has excellent taste, the down side is that unfiltered beer is quite sensitive to temperature changes, which can alter the taste of the Beer in a way that was not intended. In industry this is a two stage process, Firstly the beer passes over a series to Screens to remove sediment, Finally the beer is pasteurised, this kills and remaining organisms.

– Bottling > Your beer is ready to be bottled…. and enjoy! Home brewing & Mico brewing have become ever more popular over the passed decade, the number of such breweries has quadrupled since 2012 . The number of home brewing set ups in Europe is in the thousands. People have developed a real passion for brewing there own product and enjoy the rich flavour.

Kits for home brewing have allowed any Joe soap to develop there own Beer, Larger, Stout & Ales. Several companies in Ireland such as the Homebrew company and Homebrew west offer all the equipment to make your own refreshing pint.

Further a field companies like Home brew and biere-boutique in New Zealand and France offer a similar service. As with any thing you try first time it is not always a success, some handy tips on brewing can be found here. Typically in such a set up the Brewers buys his grain already crushed or uses a hand operated malt mill to create a Grist.

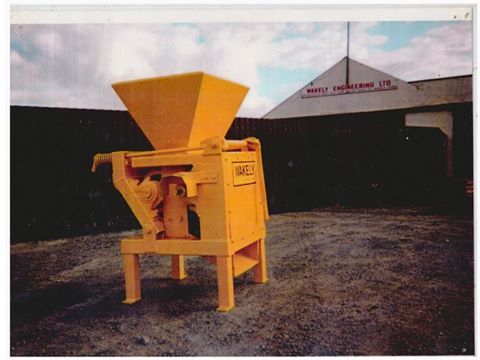

One the industrial side of things, more automation & speed is of the essence. Wakely engineering make a range of Malt mills for this industry using Two & Four roll systems. Here’s some installations that were completed recently,

[nggallery id=96]

Another Irish company which could be of assistance is Loughran stores, who stock a vast array of malted Barley and other, Contact Anthony or James fro further information.

.

Some companies who run Wakely malt mills in their system.

[nggallery id=94]

Happy brewing!